Customize press machines depending on the work contents.

VEST’s original machine lineups.

Press machine

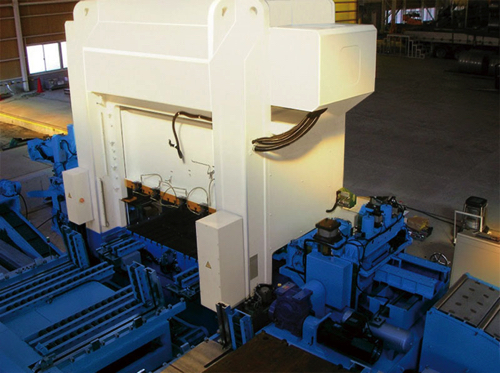

Punching press with a gate width of 4000

Straight side press with special specifications

C frame press with special specifications (changes in stroke length and die height)

Screw servo press with 2-point bottom slide

Underdrive Thomson working machine with NC table

Servo press with 4-point bottom slide

Robot

XY gripper feeder (NC control)

NC three-dimensional robot

[Click here for a video]

NC precision gripper feeder

[Click here for a video]

Robt line

Line configuration

- Leveler feeder

- Independently driven robot

- Mold hydraulic clamping system

(Robot rebuild machines also available)

Number of optimal solutions matching the number of users.

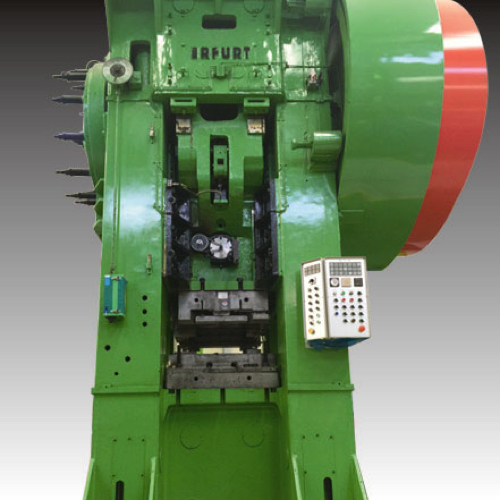

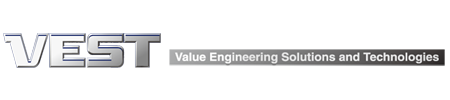

The third option Rebuild machines

Click to display the state after the rebuild

We can provide consultations on the level of the rebuild.

We sell a rebuild machine not only for a C type frame press but also for a straight side press.

A tilting press currently out of production becomes available by a rebuild machine.

Foreign-made rebuild machine

60 ton high speed press of Kyori Kogyo and AIDA ENGENEERING

(still capable of production in good shape after more than 11 years)

[Click here for a video]

Rebuild machine of AIDA ENGENEERING

20 ton rebuild machine of YAMADA DOBBY

[Click here for a video]

Field survey before rebuild

Rebuild machine at delivery

We also provide optimum molds.

Progressive working (also supports a full-turnkey)

Large progressive working line

Line configuration

- Straight side

- double crank press

- NC high tension coil line

- Oil applicator

- Product alignment equipment

- Scrap cutter

- Scrap shooter/conveyor

- Automatic mold replacement equipment

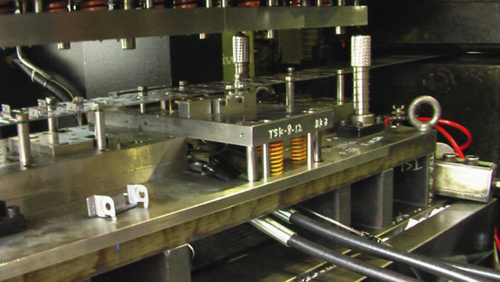

Medium progressive working line

Line configuration

- Straight side

- double crank press

- NC leveler feeder

- Oil applicator

- QDC system

- Pre-roller with pillar

- Servo tap system

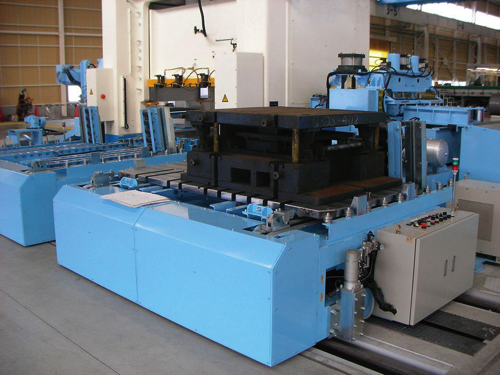

A photograph at the pre-shipment acceptance inspection at the VEST affiliated plant.

C type press working line

[Click here for a video]Line configuration

- C type press

- NC roll feeder

- Digital rotary cam

- Error detector

- Residue blowoff detector

- Coil material cleaner

- Press interlocking lubrication equipment

- Scrap n cutting equipment

- Scrap discharge system

- Product conveyor

- Turntable type uncoiler

From small press lines to large press lines

The coil line also supports a plier

The progressive mold of the three-dimensional shape product delivered to a shovel manufacturer

Presses and machines below are increasingly adopted not only in overseas plants but also in domestic plants. Please use the VEST overseas network.

Imported machine

Cold forging press

Cold forging press

Hot-forging press

[Click here for a video of a J&H 1600 ton hot-forging press]

Imported rebuild machine

Forging press working sample

In addition to main bodies of press machines, we also offer peripheral equipment such as robots and leveler feeders, etc.

Secondhand machine

We search for machines with your desired specifications from across the country.(A photograph of a 400 ton bridge link press)

Second-hand RY robots and leveler feeders are also available at an affordable price.

Power up the existing press machines with peripheral equipment.

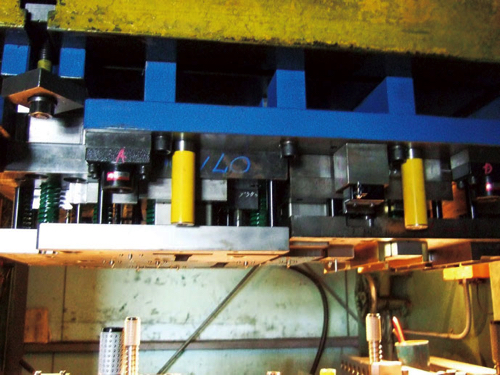

Hydraulic die cushion system

Use a general-purpose press machine to elicit performance rivaling or surpassing that of a fine blanking machine.

Die changer

Wide variations depending on the size and replacement method of molds.

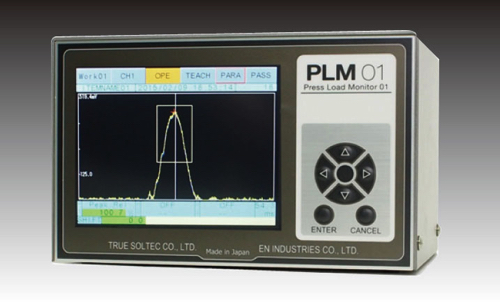

Monitor and record the working status (traceability)

Graphic load cell

Graphic bottom dead center detector

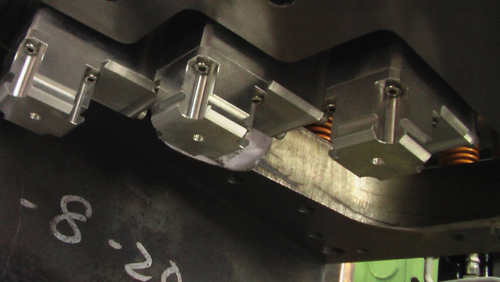

Servo tap in mold (progressive/robot)

Allows installation on an intermediate table of a robot line as well as a progressive mold.

Incorporation of a servo tap in the press process enables a great cost reduction, tact speedup, eradication of tap omissions, and quality improvement, which also promises a longer lifetime of a tapping tool.

Equipment lineups further opening up the possibility of press working

Scrap processor/Hydraulic clamp/Pre-roller/Die roller/Mold replacement equipment/Error detector/Automatic box replacement equipment/Product extraction equipment for compound mold/Coil material cleaner/And the equipment desirable for your plant

Important maintenance of press machines after delivery.

Press machine repair

Repair of press machines Ecology that realizes a prolonged lifetime of machines through maintenance.

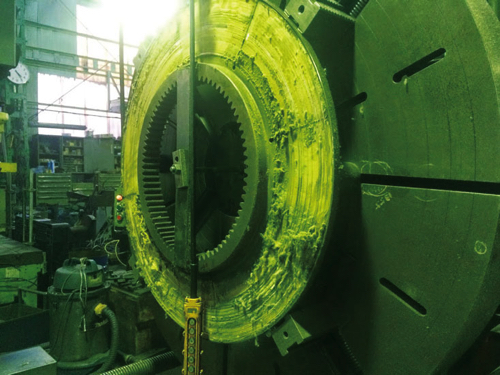

Repair of clutches / brakes

Disassembly / investigation of clutches / brakes

Additional work of bolsters

Replacement of clutch linings

Mechanics

Due to this press having a broken frame, rebuilt a frame. (mechanical working while breathing fire)

Frame

Electricity

Inspection of a servo press

Hydraulic pressure

You can count on us for maintenance of hydraulic devices.

Press peripheral equipment

Peripheral equipment also revives by replacing parts.

Field repair of coil lines

NC leveler feeder

〈Before retrofit〉

NC leveler feeder

〈After retrofit〉

In many cases, a servo motor and an electric control board become non-usable while a mechanical part is still usable. Replacing servo motors or electric control panels, or rebuilding operation panels provides a longer lifetime of leveler feeders.

Press machine relocation

Weight transportation work entails an important work for installing a press machine.

Towing work (Large press)

Towing work (C type press)

Lift the contents in the field

Transport by trailer

VEST also supports the field of molds, the essence of press work.

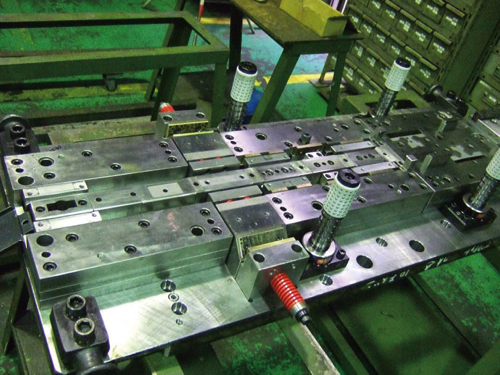

Sales of molds tailored to applications

Molds for U.S. plants for domestic automobile parts

We manufacture molds suited for customer specifications

Three-dimensional shape progressive molds

Machine tools for molds

Wire cut electric discharge machine

Machining center

CAD/CAM

Recently, more and more young designers go straight to the three-dimensional CAD, rather than the two-dimensional CAD.

Privacy policy

Privacy policy

[Click here for a video of the rebuild machine of Bruderer Presses]

[Click here for a video of the rebuild machine of Bruderer Presses] [Click here for a video of a 20A rebuild machine (in operation by a user)]

[Click here for a video of a 20A rebuild machine (in operation by a user)]

[Click here for a video of a progressive mold servo tap]

[Click here for a video of a progressive mold servo tap] [Click here for a video of a repaired friction press]

[Click here for a video of a repaired friction press] [Inspection of a servo press]

[Inspection of a servo press]